- WMS warehouse management system

- WCS warehouse control system

- Digital workshop

- EBR electronic batch record

- Paperless system

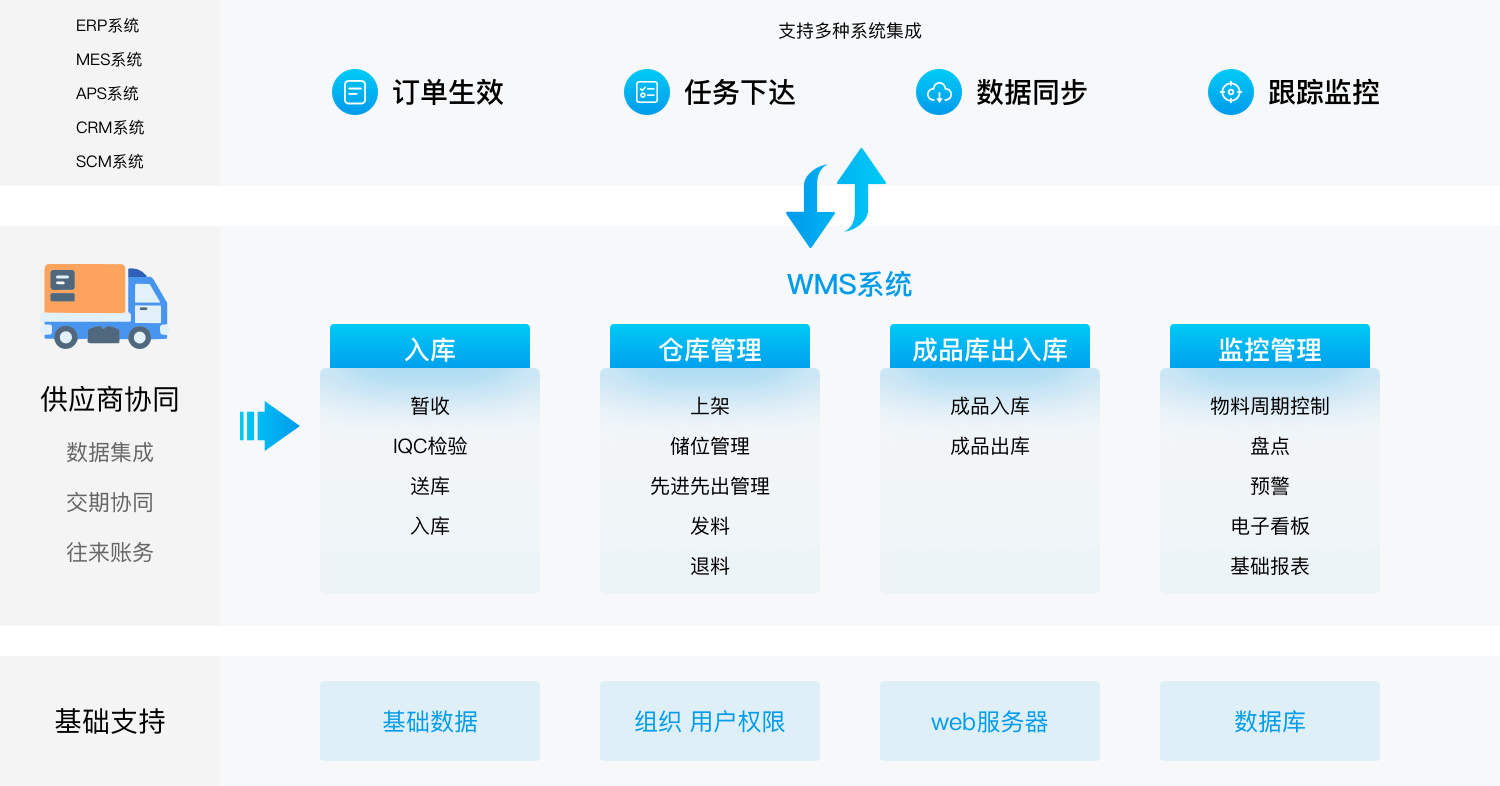

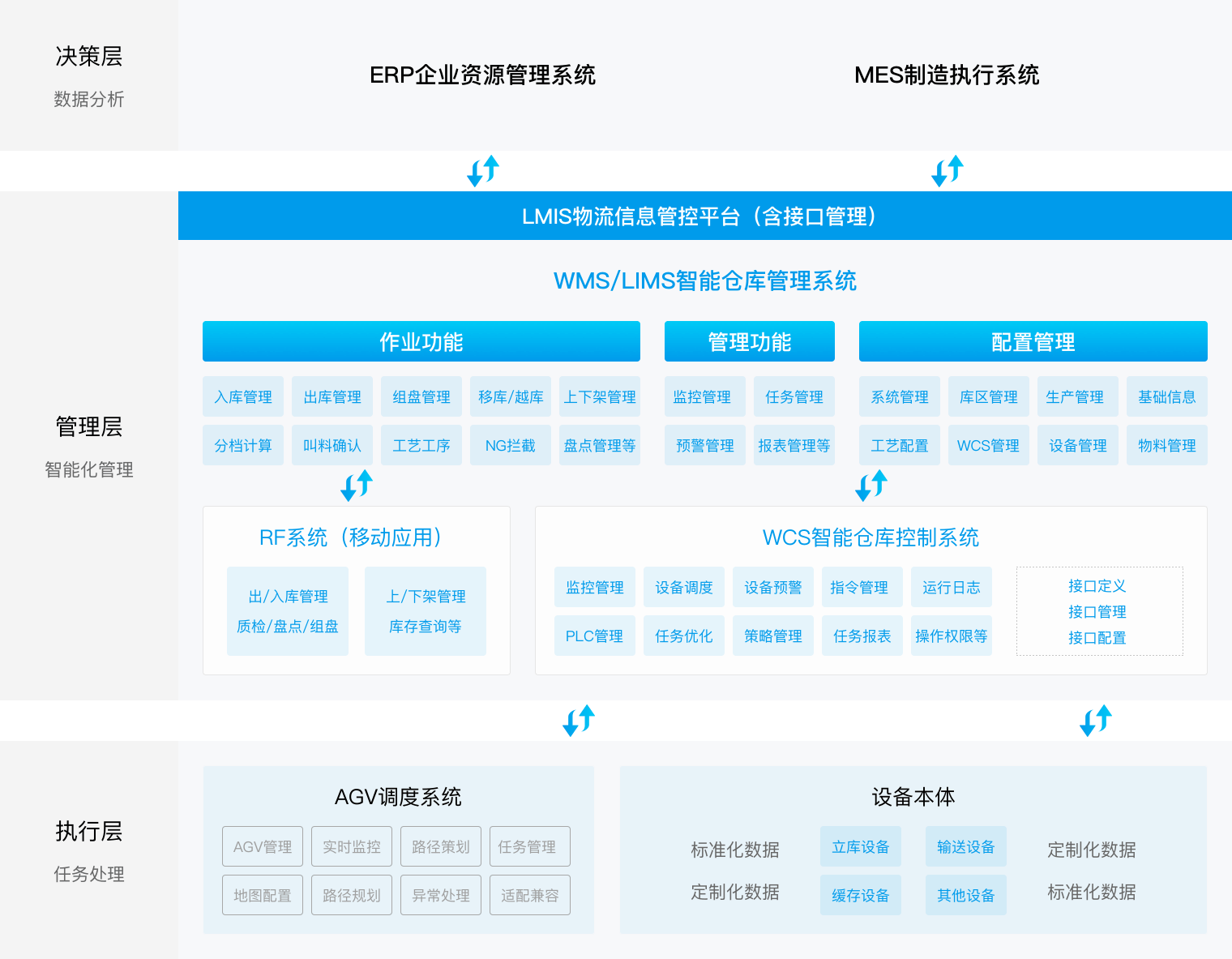

WMS warehousing management system is an information synchronization and collaborative execution system specially developed for the warehousing and logistics needs of manufacturing factories.

WMS can effectively improve the coordination efficiency of multi-departments related to materials, deal with complex material in and out of warehouse business, cover the implementation efficiency of material flow from suppliers, raw material warehouse, line-side warehouse, in-process circulation, finished product delivery and e-commerce third-party logistics, and lay the foundation for complete batch traceability and MES process control.

-

Optimize warehousing operations to improve overall efficiency

Departmental interconnection

Scan as input

FIFO planning

Space identification refinement

Multiple stocktaking schemes

Merge work orders

-

Source identification scan warning to eliminate errors

Scan into the box, automatically check and alarm, put an end to man-made packaging errors

Support packaging update, product replacement, background data automatic update

-

Strong forward and reverse tracing the whole process of error correction and prevention

Batch information inheritance, clear material source

-

Automatic early warning to prevent stupor and lag

Automatic alarm, reminder failure and time-out of storage

Close to failure period, automatic alarm

In WCS, the running position, job status, running failure and other information of the main equipment are simulated and displayed in the way of animation.

The main features include:

1.Decompose the received task instructions into the action instructions of the device, and optimize the instruction queue.

2.Intelligent scheduling to send action instructions to the device controller PLC and monitor its execution results

3.Real-time display of system running status and occupancy of goods space;

4.Record, display and deal with equipment faults, use historical database to facilitate problem tracking and handling;

-

Rich and powerful communication interface

Independent development program, using a variety of connections

Support a variety of PLC docking: Siemens, Schneider, OMRON, Delta, etc. have rich experience in communication control.

Problem quick detection scheme: real-time early warning of exception flow, and exception handling scheme is given.

-

Intelligent logistics electronic Kanban

Including Layout display, location monitoring, data reports and other pages

Use Android TV and load it through Android APP mode

Wirelessly, no need to be wired

The position of Kanban can be adjusted at any time.

Can integrate Dashboard business dashboard

-

Rich and powerful communication interface

Independent development program

Support multiple PLC docking

Choose technical solutions according to different business scenarios

Problem Quick check Program

-

Rich and powerful communication interface

Independent development program

Support multiple PLC docking

Choose technical solutions according to different business scenarios

Problem Quick check Program

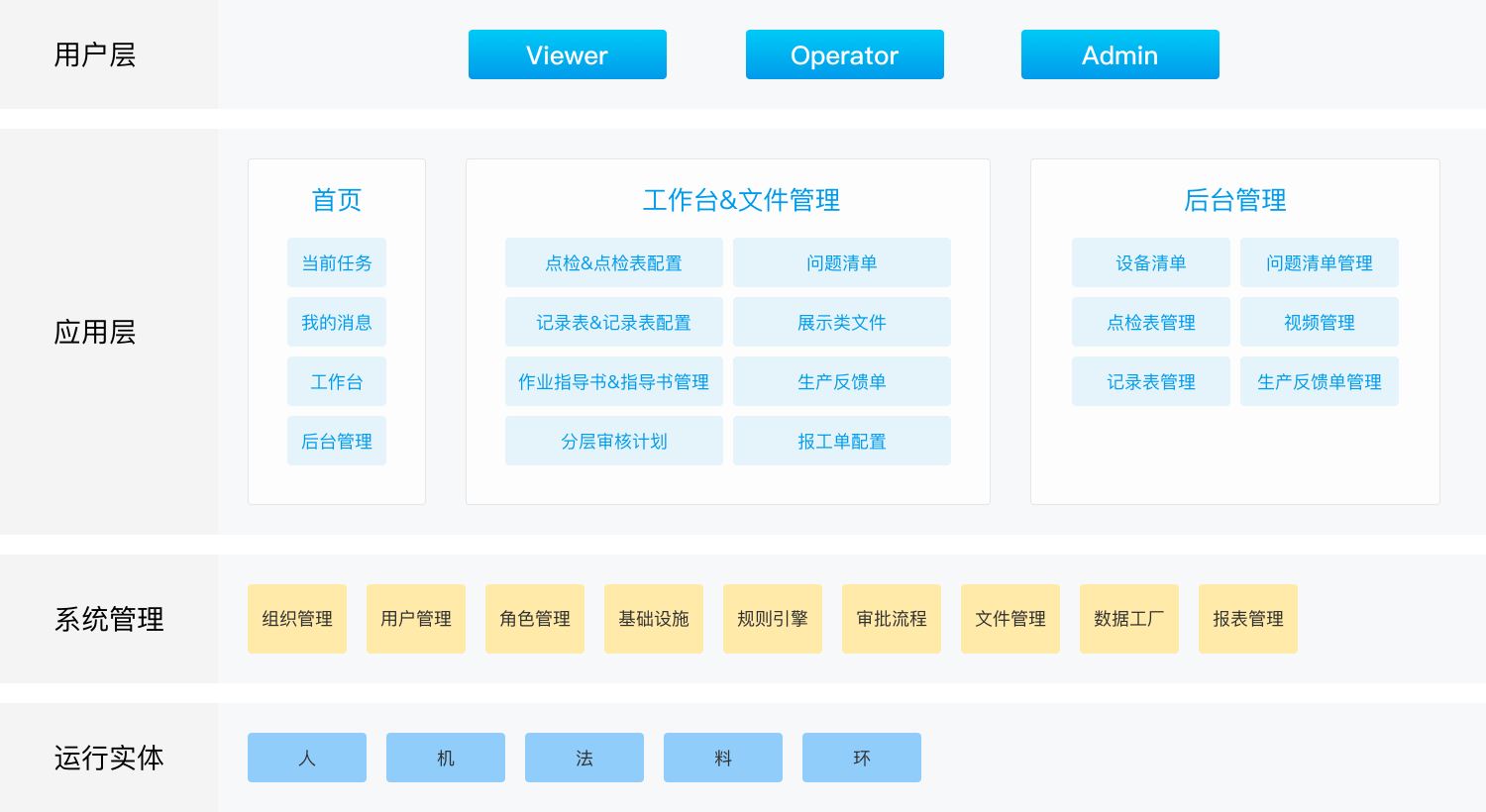

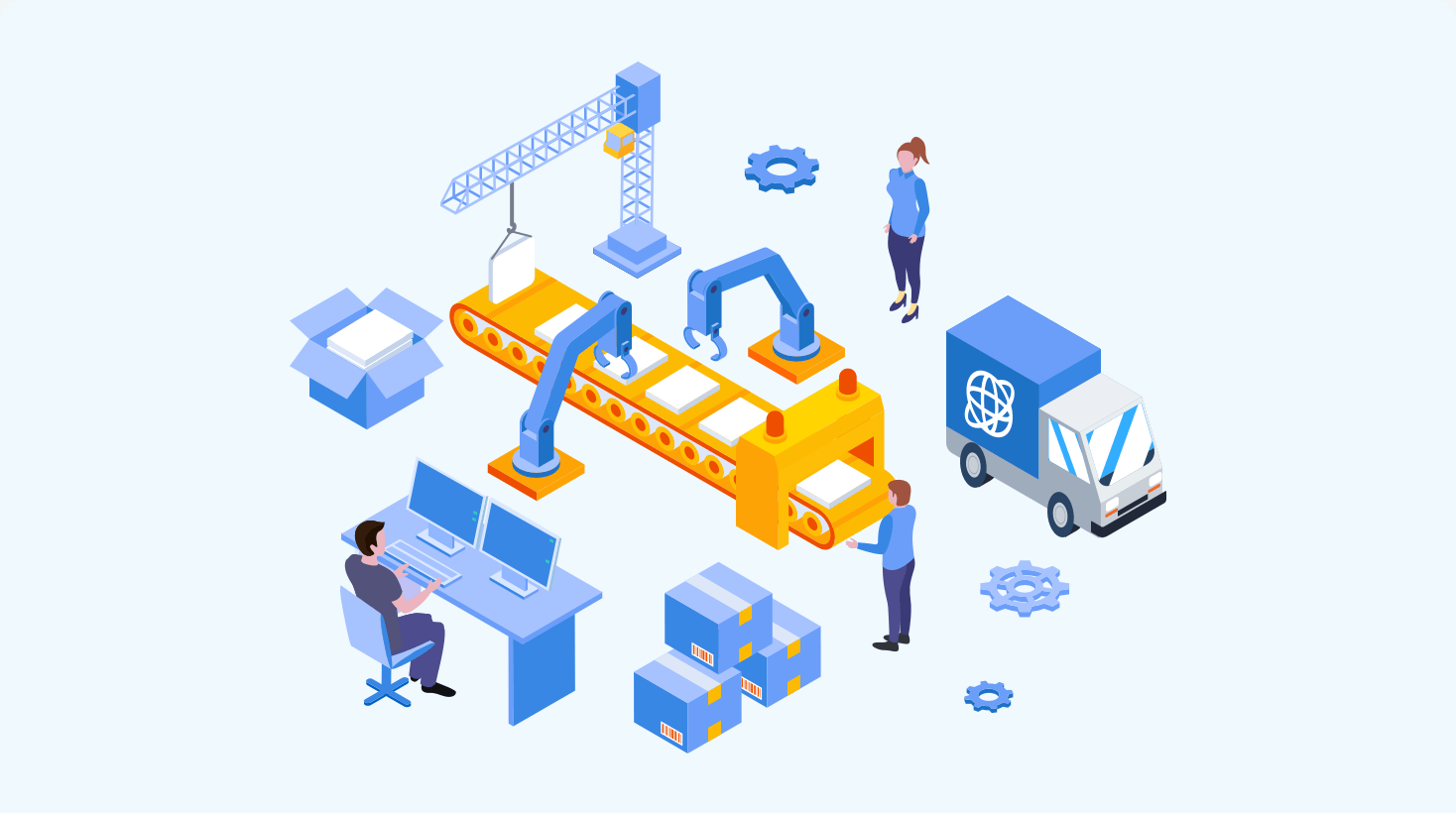

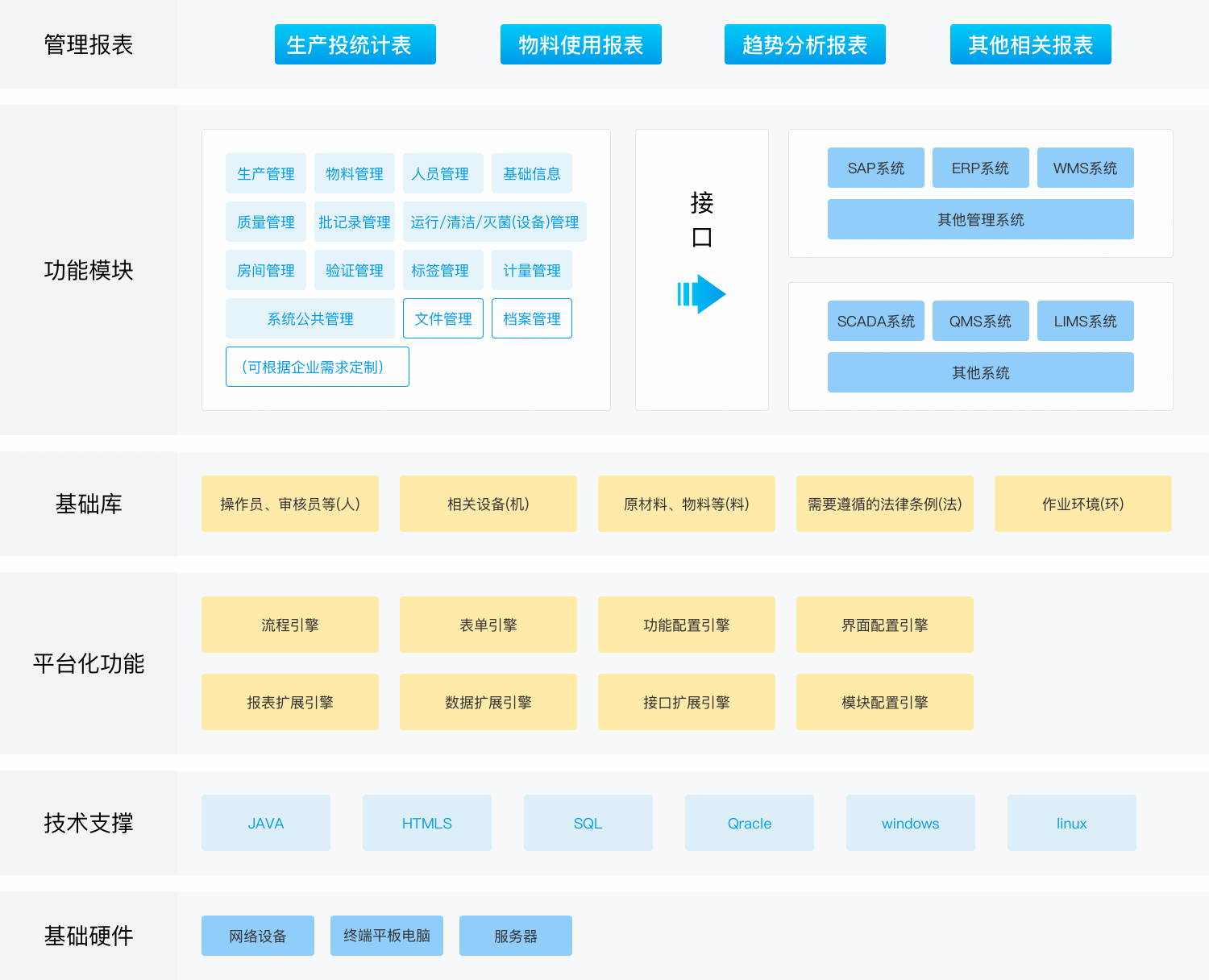

Digital workshop is an advanced workshop, which uses digital technology to manage and optimize the manufacturing process.

- Flexible production process

- Digital manufacturing

- Data-driven decision making

- Highly connected Devic

-

Flexible production process

The production process of the digital workshop is more flexible and can quickly adapt to market changes and customer needs. Through digital design and simulation technology, the manufacturing process can be simulated and optimized before actual production, and the cost of trial and error is reduced.

Learn more -

Digital manufacturing

Digital workshop uses digital technology for manufacturing, from design to production, all processes are managed and optimized by digital means. This makes the manufacturing process more accurate and predictable and reduces errors in product development and production.

Learn more -

Data-driven decision making

The digital workshop optimizes the manufacturing process by collecting and analyzing production data and using data-driven decision-making methods. This can improve product quality, reduce costs and reduce waste.

Learn more -

Highly connected Devic

The digital workshop optimizes the manufacturing process by collecting and analyzing production data and using data-driven decision-making methods. This can improve product quality, reduce costs and reduce waste.

Learn more

Production scheduling

Visual and transparent production site, rapid response to sudden production problems; flexible arrangement of production operations without relying on all kinds of manual and paper documents

Production execution

Convey on-site production information in the way of large information screen to improve the efficiency of collaborative execution and management.

Material management

Carry out unified coding control of raw materials, track the sources of raw materials, decompose and refine the process plan, adjust the production plan according to the tracking of raw materials, and be able to warn against the ups and downs of the actual purchase plan and planning progress of raw materials to avoid inventory accumulation.

Quality inspection

Connect intelligent detection hardware, support Bluetooth and other docking methods to automatically obtain measurement data; make product inspection plan, record product defect type and other information, generate inspection results for follow-up analysis

Production newspaper worker

Realize automatic report and note-keeping

Improve the correct rate of wage accounting

Software equipment

Combine "application software + infrastructure hardware" to realize the visualization, tuning and control of factory information and data.

Product traceability

Support rapid backtracking of production information, query the records of all stages of the production process, and accurately locate the specific operator, machine and production parameters

Warehousing management

Follow the first-in-first-out principle of materials to realize the integrated warehouse management and control of "real-time query, material exchange and dynamic replenishment".

Equipment interconnection

Using low-cost factory equipment information data to collect connected equipment information to improve equipment utilization

Operation analysis

Through the data visualization and real-time monitoring of each module, it provides a basis for managers to adjust production decisions in time.

1.The system is a management software specially developed for batch management.

2.The working modules in the system provide sequential, parallel and branch instruction processing to meet the requirements of different process routes.

3.The system can execute the electronic process according to the standard operating flow of production, and automatically generate complete production batch records.

4.The system can provide complete record traceability, batch history information, and audit tracking records.

- Complianc

- Continuity

- Traceability

- Automation

-

Complianc

Track production records and link to specific attachments, such as standard operating documents and related laws and regulations (FDA, cGMP, etc.) to ensure compliance with each batch of production records

Learn more -

Continuity

So that the production batch records have the ability of continuous tracking, the batch release of traditional records can only be queried a few days after data entry, and the release time is reduced by 50% after using EBR system.-80%

Learn more -

Traceability

Preset login permission requirements (such as user name and password, etc.) and login permissions are bound with electronic signatures to ensure traceability of each production and audit process

Learn more -

Automation

Realize electronic and automatic production records and paperless office.

Learn more

Paperless system is an efficient, intelligent and environmentally friendly office solution, which can help enterprises to achieve automation and paperless office, and improve work efficiency and productivity. At the same time, the paperless system is also suitable for government agencies, medical institutions and other fields, and has a wide application prospect.

1.Business process automation: paperless system can automate all kinds of office processes, such as application, approval, reimbursement, etc.

2.Data analysis: paperless system can analyze the data generated by office process and provide data support for enterprise decision-making.

3.Report generation: paperless system can generate all kinds of reports automatically, which is convenient for enterprises to manage and monitor.

- High efficiency

- Intelligence

- Save cost

- Environmental protection

-

High efficiency

The system can automatically deal with all aspects of the production process and improve the production efficiency and management efficiency.

Learn more -

Intelligence

The system can realize the intelligent management of the production process, optimize and predict the production through data analysis, and improve the production quality and efficiency.

Learn more -

Save cost

The system can not only reduce paper and printing costs, but also reduce labor costs and management costs.

Learn more -

Environmental protection

The system can reduce the production of paper and printing waste and is environment-friendly.

Learn more